THE CORRUGUARD ADVANTAGE

“Make it a priority that your company is always becoming better at what it does. Committing to a process of continuous improvement means a constant focus on improving productivity and quality. It’s a process that never stops.” (“Business agility: 8 steps to improve reaction time” – BDC)

Packaging … While some see it as a necessary evil, others seize every opportunity to stand out by optimizing their operations. Successful companies that manage to outrun their competition are those that leave nothing to chance and make continuous improvement a priority.

In a world where productivity and efficiency are vital in business, every step of your operations must be evaluated for the potential gains to be achieved and it is in the packaging that our company stands out! Through a committed partnership, Corruguard supports Canadian industries by developing unique, ecological and efficient packaging solutions that meet their challenges of productivity, versatility and cost reduction.

Made from a 26-26 lb premium Flute C single-sided roll, we laminate up to 5 layers of thickness to produce a corner customized to your dimensions. Corruguard is the only company in Canada that uses this raw material to manufacture its corners and this distinction allows it to stand out in several facets.

Although there is very little competition when it comes to a delivered preformed corrugated corner, there are several substitutes that each offer arguments that may attract companies:

FOAM

Once king of packaging for its shock absorbing qualities and inexpensive filling capabilities, the costs often associated with manufacturing dies and its crumbly side have sometimes caused users to look for other options. On the other hand, it is mainly its pitfalls in recycling and an increasing awareness of the environment as well as new laws restricting its use in certain places in the world that have dethroned it from its pedestal. At a time when marketing takes all forms and when consumers are more rigorous in choosing their supplier according to their values, companies are being forced to develop their responsibility and to make increasingly judicious choices. Fortunately for them, other options exist and will satisfy their selection criteria.

The MOLDED FIBRES CORNER

Made of recycled cardboard fibres, its ecological aspect is interesting but its versatility is a little less like its cost. Although valued in specific contexts, it must be said that since a mold is necessary for its manufacture, you will have to choose from the existing models. Regarding its protection, reviews are mixed, but that depends on its design, among other things.

The RIGID CORNER

Favored as a pallet corner, its structure and rigidity give it a real advantage for this use. But how about when used as protection directly on a piece of furniture, for example? First, you will have to go to the saw for each of your cuts which is very unproductive … Second, hard as wood, the shock wave upon impact is directly transferred to your furniture which is now damaged. Nothing absorbed the shock and here you are stuck with a return to the manufacturer. Of course, we will be told that its price is interesting, but companies that have access to complete information on their business know the costs associated with returning a damaged piece of furniture: repair, administration, transport, time, the delay on payment not to mention the bad impression left to the buyer … Too many costs and time delays that cannot be neglected. And with the fierce competition, who can afford to disappoint a customer these days?

The SCORED SHEET

Delivered flat, the sheet is very affordable. You can choose its thickness and shape, but a cutting die may be necessary to obtain a custom product. Nevertheless, it doesn’t necessarily rhyme with productivity and the protection capacity depends on its manufacturing. In fact, designed to bend as easily as possible during use, the score often tends to weaken the cardboard, which leaves the packaged product vulnerable to the point where maximum protection is needed, its edge. On the productivity side, bending hundreds of corners a day for a product which tends to come back flat as soon as it is released brings its share of difficulty.

With all of these options available, why do Canadian companies decide to work with Cartons Corruguard’s corrugated corners? I just thought I would leave you with some success stories from our clients …

We work with a large company that has over 200 employees and manufactures furniture. It was while working with one of their production managers that I realized that their next step was to fully automate their packing station using robotization. To facilitate this future transition, but also to facilitate the work of the current operator and increase productivity, it was necessary to move from the flat sheet to the preformed Corruguard corner. The transfer was a success.

We work with manufacturers of aluminum railings who were struggling to hold their length of cardboard in place while trying to wrap it all up. Today, those same companies are working with the closed U-Guard. Formed on three sides and two sharp angles, the cardboard U closes over the ramp like a clamp to hold itself in place while waiting to be secured by the plastic wrap.

A large door and window manufacturer with more than 300 employees called on our biggest competitors to develop an adhesive product to affix to its windows. After a few unsuccessful months, Corruguard was called to the project. After nearly three years of research and development, we were able to offer a unique corner! The narrowest on the market so as not to block the shutter, but above all an adhesive croner that leaves no residue.

Another large window manufacturer had to find a safe solution to replace its current corner because an employee stapled one of his fingers while putting it down. Corruguard’s preformed corner solved the problem considering that employees no longer have to hold the cardboard on the side to be stitched. The CNESST is satisfied and meanwhile the company becomes more efficient.

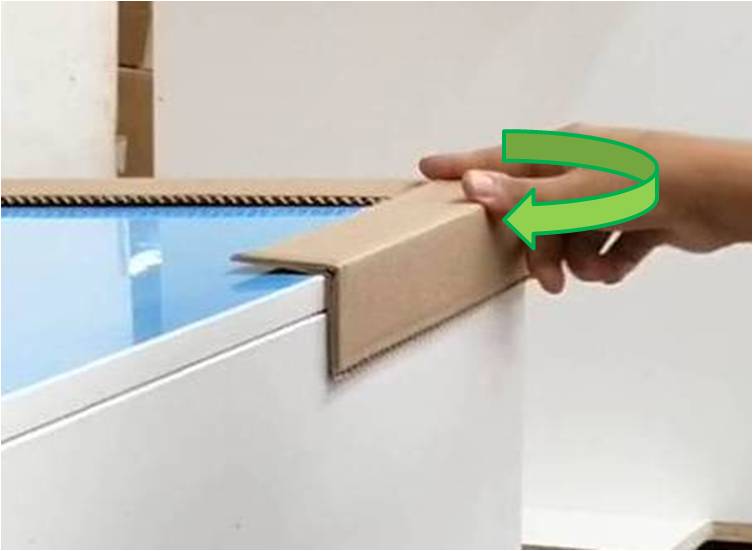

The rigid corner is often replaced for reasons of efficiency. After all, what business can afford to have someone go back and forth between the saw and the packing station to cut their pieces to measure? Furthermore, the angles thus cut are joined and superimposed on the furniture’s corner but if they only move ever slightly, the furniture’s corner’s edge can be exposed. The Corruguard corner is flexible by the direction of its undulation, so you can bend it to measure to turn around the products and guarantee effective protection of the furniture’s corner’s edge. If you want to rip it, just turn it the other way around and the cardboard tears along the corrugation for a custom fit to your products.

One of our clients was urgently looking to replace his current supplier over service and timing issues. Needing a foolproof solution against breakage, we offered a tailor-made solution: a 4-ply cardboard corner notched to turn the corner and the addition of a rigid plastic wedge to increase protection by distributing the shock on the cardboard.

What about your business? What aspects of your packaging could be improved?

- Service

- Delivery delay

- Versatility

- Ecological

- Efficient application

- Support for product development

- Etc

Contact us! It will be our pleasure to work with you in developping a successful solution for your specific needs. Our main purpose:

Being an accomplice in the success of our clients.

Marie-Hélène Hotte, CEO Cartons Corruguard